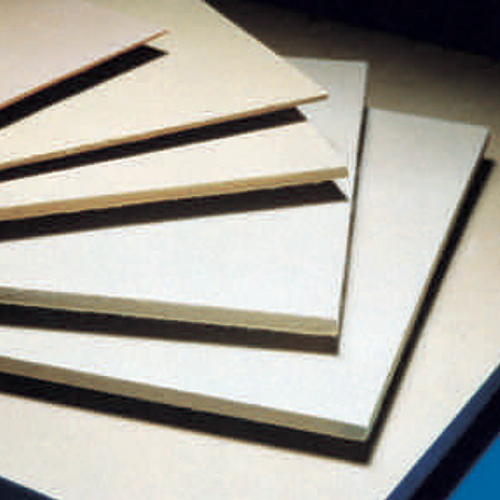

Manufactures of Non-Asbestos Ceramic Millboard Sheet

We offer Non-Asbestos Millboard Sheet that is fabricated from selected clean, long non-asbestos fibres of uniform quality assorted with suitable incombustible binding materials. These Ceramic millboards are known for its features such as heat and fire resistance and strength. Our non-asbestos millboards are perfect at temperatures up to 500°C (932`F) and even higher temperature when properly supported. Additionally, it can be used acceptably at extreme temperature up to approximately 1400`C. These are also known for its features Such as withstanding vibratory and impact loads easily.

Available is soft, medium and hard grades, these sheets can be cut, drilled and screwed to supporting beams, and can be moulded or cemented to any shape. The medium grade is supplied only if it is specially asked by our clients. The hard grade is stiff and brittle and is used where rigidity is needed.

Features :

High temperature tolerance

Strength

Can easily withstand vibratory and impact load

Available in various grades

Acid, sound and vermin-proof

Strong and flexible

Packing Method :

Non-Asbestos millboard Sheet is packed into wooden crates of approx 110 kilogram.

Number of sheets in one crate varies according to board thickness.

Board thickness in MM |

No. of sheets per crate |

3.0 |

30 |

4.0 |

25 |

5.0 |

20 |

6.0 |

15 |

10.0 |

9 |

12.0 |

7 |

Applications :

The Non-Asbestos Ceramic Millboard Sheet offered by us find wide application in boiler and furnaces, catering equipment and steel, ferrous, , non-ferrous plants. Various uses are stated below:

Boilers and Furnaces :

Bedding layers on floor tiles in boiler house.

Refractory underlining

Damper control heat insulators

Boiler door linings

Gaskets for burners and ducting

Catering Equipment :

Heating appliances such as Domestic,

Cookers, and Grills

Flue gas and burner seals

Combustion chamber linings

Heat shield panels

Steel, Ferrous and Non-Ferrous Plants :

Steel and Aluminium making processes

Centrifugal casting seals

Induction furnace coil protection

Splash guards